Currently, communication technology has become an indispensable part of modern vessels. Whether used for navigation, communication, entertainment, or other critical systems, reliable signal transmission is fundamental to ensuring the safe and efficient operation of ships. Marine coaxial cables, as vital communication transmission media, play a significant role in shipboard communication systems due to their unique structure and excellent performance. This article will provide a detailed introduction to the structure of marine coaxial cables, aiming to help you better understand their design principles and application advantages.

Basic Structure Introduction

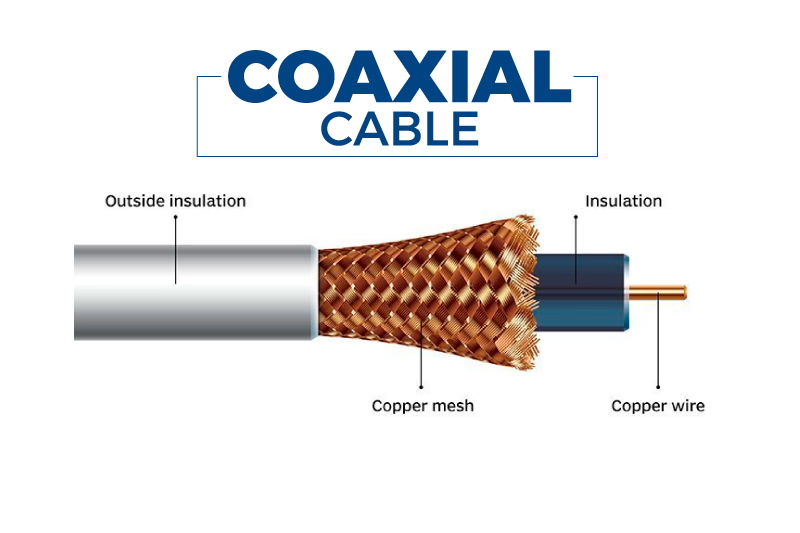

1. Inner Conductor

The inner conductor is the core component of a marine coaxial cable, primarily responsible for transmitting signals. Its performance directly affects signal transmission efficiency and quality. In shipboard communication systems, the inner conductor carries signals from transmitting equipment to receiving equipment, making its stability and reliability crucial.

The inner conductor is typically made of high-purity copper. Copper possesses excellent electrical conductivity, ensuring minimal signal loss during transmission. Additionally, copper offers good mechanical properties, allowing it to withstand certain mechanical stresses. In some special applications, the inner conductor may be made of silver-plated copper to further enhance electrical conductivity. Silver-plated copper combines the conductive properties of copper with the low resistance characteristics of silver, performing exceptionally well in high-frequency signal transmission.

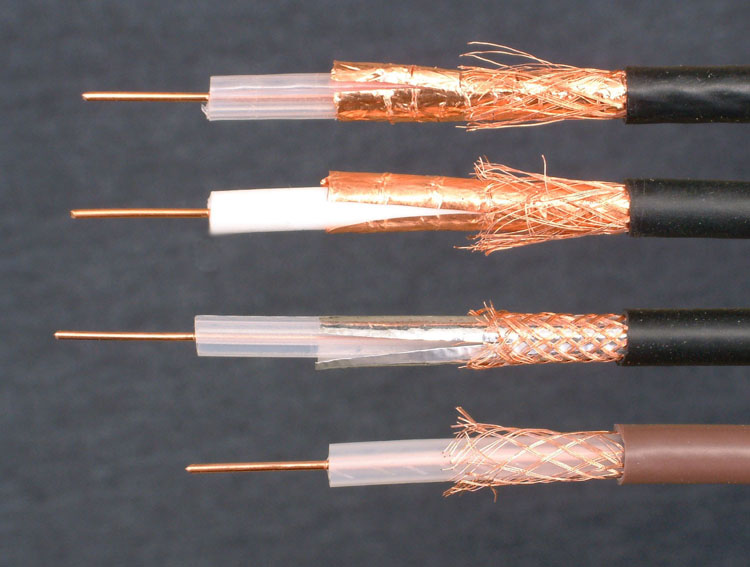

The manufacturing process for the inner conductor includes copper wire drawing and plating treatment. The drawing process requires precise control of the wire diameter to ensure the conductor’s electrical performance. Plating treatment can improve the conductor’s corrosion resistance and mechanical properties. In more demanding applications, the inner conductor may employ multi-layer plating technology to further enhance performance. For example, a multi-layer plating consisting of copper, nickel, and silver provides better conductivity and corrosion resistance.

The diameter and shape of the inner conductor have a significant impact on the transmission performance of the coaxial cable. For marine coaxial cables, the inner conductor’s diameter typically needs to be optimized based on specific transmission requirements to ensure stable transmission in the marine environment. For instance, high-frequency signal transmission requires a thinner inner conductor to reduce signal attenuation, while low-frequency signal transmission can use a thicker inner conductor to improve signal strength.

2. Insulation Layer

The insulation layer is located between the inner and outer conductors. Its main functions are to prevent signal leakage and short circuits, isolating the inner conductor from the outer conductor. The insulation material needs to possess good electrical insulation and mechanical properties, ensuring signal stability and integrity during transmission.

The insulation layer of marine coaxial cables must also feature salt mist corrosion resistance to meet the special requirements of the marine environment. Common insulating materials include Foam Polyethylene (Foam PE), Polytetrafluoroethylene (PTFE), Polyethylene (PE), Polypropylene (PP), and others. These materials not only offer excellent insulating properties but can also withstand certain temperature variations and chemical corrosion.

The thickness, uniformity, and concentricity of the insulation layer significantly affect the cable’s transmission performance. The insulation layer needs to be sufficiently thick to prevent signal leakage but should not be excessively thick, as this would increase cable weight and cost. Additionally, the insulation layer must have good flexibility to accommodate cable bending and vibration.

3. Outer Conductor (Shielding Layer)

The outer conductor, or the shielding layer of the coaxial cable, primarily functions to shield against external electromagnetic interference, ensuring signals are not disrupted during transmission. The design of the outer conductor must consider anti-electromagnetic interference and anti-vibration performance to guarantee signal stability during ship navigation.

The outer conductor is usually made of braided metal wire, which offers good flexibility and shielding performance, effectively reducing electromagnetic interference. The braiding process requires precise control of braid density and angle to ensure the shielding performance of the outer conductor. The braided outer conductor undergoes heat treatment to enhance its mechanical properties and conductivity.

Shielding effectiveness is a crucial indicator for measuring the performance of the outer conductor. Higher shielding attenuation indicates better anti-electromagnetic interference performance. Marine coaxial cables require high shielding attenuation performance to ensure stable signal transmission in complex electromagnetic environments. Furthermore, the outer conductor must possess good flexibility and vibration resistance to adapt to the mechanical environment of ships.

To improve anti-electromagnetic interference performance, marine coaxial cables often employ structures like double shielding or triple shielding. A double-shielded structure includes a layer of braided metal wire and a layer of aluminum foil, effectively reducing the impact of external electromagnetic interference on signal transmission. This is particularly effective in complex electromagnetic environments, such as in a ship’s radar and satellite communication systems.

4. Sheath

The sheath is the protective layer of the coaxial cable, serving to protect the cable from external environmental erosion. For marine coaxial cables, the sheath material must possess properties such as salt mist corrosion resistance, abrasion resistance, and flame retardancy to ensure cable reliability and safety in harsh environments.

Common sheath materials include Low Smoke Zero Halogen (LSZH) polyolefin, Polyurethane (PU), Polyvinyl Chloride (PVC), and Polyethylene (PE). These materials protect the cable from external environmental erosion. LSZH materials do not produce toxic smoke when burned, meeting the strict requirements of the International Maritime Organization (IMO) and classification societies (DNV, ABS, CCS, etc.). To enhance ship safety, marine coaxial cable sheath materials typically use LSZH materials, which not only reduce hazards to crew in case of fire but also minimize environmental pollution.

Special Structures

1. Armor Layer

In situations requiring additional mechanical protection, an armor layer is added to the structure. The armor layer is typically made of steel wire or steel tape, effectively enhancing the cable’s mechanical properties and preventing damage in harsh environments. For example, in ship anchor chain lockers or on decks, armored coaxial cables can withstand mechanical impact and abrasion, ensuring stable signal transmission.

2. Waterproof Layer

Due to the high humidity of the marine environment, marine coaxial cables often include a waterproof layer to prevent moisture penetration into the cable interior, avoiding interference with signal transmission. The waterproof layer is usually made of special waterproof materials that not only provide good waterproofing performance but also offer a degree of mechanical protection.

Summary

The structural design and material selection of marine coaxial cables are key to their ability to transmit signals stably and reliably in harsh marine environments. The various components together form an efficient and stable signal transmission system. Through different structural optimization designs, marine coaxial cables meet the stringent requirements for signal transmission.

With the continuous development of shipboard communication technology, marine coaxial cables will continue to play a crucial role in vessels’ radar systems, satellite communication systems, navigation systems, and entertainment systems, providing robust support for the safe and efficient operation of ships.

Post time: Dec-17-2025