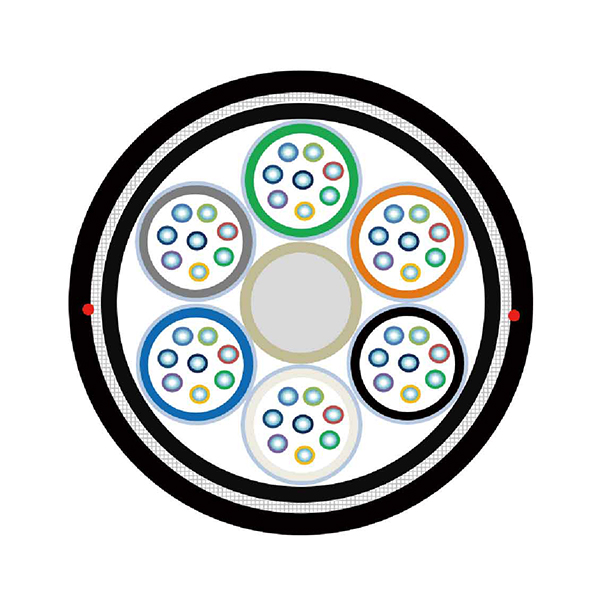

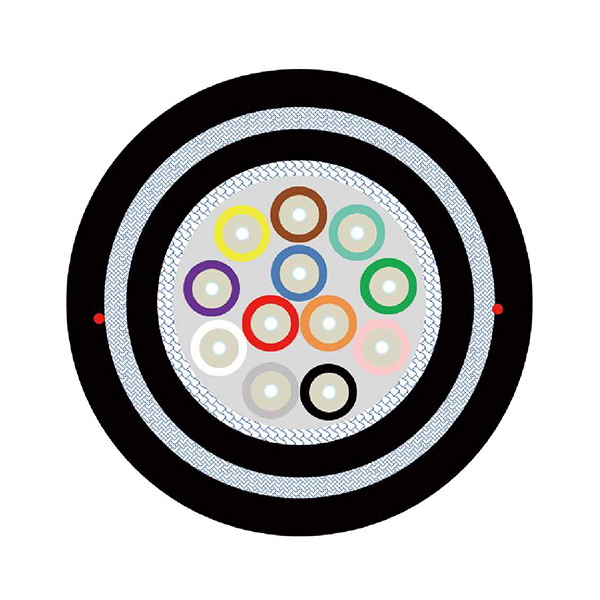

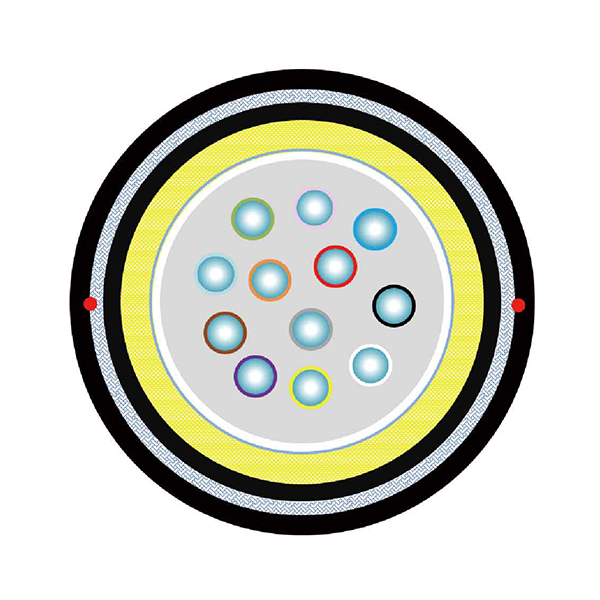

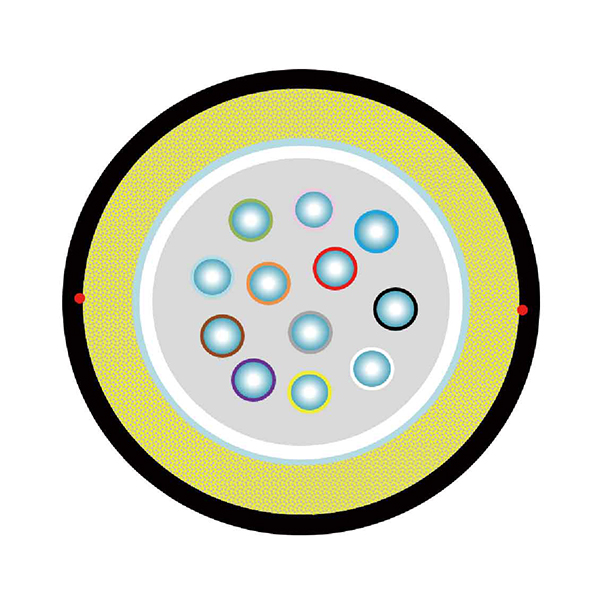

QFCI/B Multi loose tube metallic armored fiber optic cable

| Fiber: | Loose tube |

| Strength member: | Centre steel wire or dielectric central core |

| loose tube diameter: | Normal Ф2.2 mm |

| Color code: | Individually colored fibers |

| Fire resistant layer(Option): | Mica tape |

| Peripheral strength element: | Water blocking yarn, when necessary |

| Inner jacket: | SHF1 |

| Armor: | Alt.1: Galvanized steel wire braid – GSWB Alt.2: Corrugated steel tape |

| Outer jacket: | QFCI: GSWB or Corrugated steel tape + SHF1 QFCB: GSWB or Corrugated steel tape + SHF2-MUD |

| Outer jacket color: | Black (As per request) |

| Halogen acid gas, degree of acidity of gases: | IEC 60754-1/2 |

| Jacket, insulation material: | IEC 60092-360 |

| Smoke emission: | IEC 61034-1/2 |

| Flame retardant: | IEC 60332-3-22 |

| Oil resistance: | IEC 60811 |

| Mud resistance: | NEK 606 |

| Fire resistant: | IEC 60331-25 |

| UV-resistant: | UL 1581 |

| Bending radius (N/10cm)-Long-term: | 20D, 25D (Corrugated armor) |

| Bending radius (N/10cm)-Short-term: | 15D, 15D (Corrugated armor) |

| Temperature (°C)-Operation: | -40°C~70°C (SHF1) |

| Temperature (°C)-Installation: | -40°C~80°C (SHF2, SHF2 MUD) |

| UV-resistant: | -10°C~60°C |

| No. of fiber | No. of tubes x fibers per tube + Fillers | Inner sheath OD (mm) | Outer sheath OD (mm) | Tensile (N) | Crush (N/10 cm) | Cable weight (kg.km) |

| 4 | 2×2+2 | 10.1 ± 0.5 | 13.5 ± 0.5 | 2000 | 3000 | 260 |

| 8 | 2×4+4 | |||||

| 12 | 3×4+3 | |||||

| 24 | 4×6+2 | |||||

| 48 | 4×12+2 |

| Standard Designation | Maximum Attenuation (dB/km) | Fiber Diameter (μm) | OFL Bandwidth | EMB at850 nm (MHz·km) | ||||||||

| IEC 60793-2-50 | IEC60793-2-10 | IEC11801 | ITU-T | 850 nm | 1300 nm | 1310 nm | 1550 nm | 1625 nm | 850 nm (MHz·km) | 1350 nm (MHz·km) | ||

| B1.3 | — | OS2 | G652D | — | — | 0.4 | 0.3 | 0.25 | 8.6-9.5 | — | — | — |

| B6_a1 | — | — | G657A1 | — | — | 0.4 | 0.3 | 0.25 | 8.6-9.5 | — | — | — |

| B6_a2 | — | — | G657A2 | — | — | 0.35 | 0.25 | 0.25 | 8.2-9.0 | — | — | — |

| B6_b3 | — | — | G657B3 | — | — | 0.35 | 0.25 | 0.35 | 8.0-8.8 | — | — | — |

| — | A1a.3 | OM4 | — | 3.2 | 1.2 | — | — | — | 50±2.5 | ≥3500 | ≥500 | 500 |

| — | A1a.2 | OM3 | — | 3 | 1 | — | — | — | 50±2.5 | ≥1500 | ≥500 | 2000 |

| — | A1a.1 | OM2 | — | 3 | 1 | — | — | — | 50±2.5 | ≥500 | ≥500 | 4700 |

| — | A1b | OM1 | — | 3.2 | 1.2 | — | — | — | 62.5±2.5 | ≥200 | ≥500 | 200 |

Write your message here and send it to us