Recently, Yanger (Shanghai) Marine Technology Co., Ltd. has announced exciting news—its core products, marine Ethernet cables and marine fiber optic cables, have successfully passed the authoritative certification of Lloyd’s Register (LR) and officially obtained the LR Type Approval Certificate! Founded in 1760, Lloyd’s Register is the world’s earliest established classification society. For over 260 years since its inception, it has been dedicated to the maritime industry, continuously improving ship safety and promoting the sustainable development of the ocean economy.

This breakthrough achievement of our specialized cables receiving LR recognition signifies that our products have reached international top standards in terms of technological R&D and quality control, demonstrating core competitiveness in the global maritime equipment field. It provides more reliable communication solutions for the global shipping industry.

High-Efficiency Transmission: Building a Maritime Communication “High-Speed Channel”

This certification covers our marine Ethernet cables ranging from CAT5E to CAT7A to meet multi-scenario application needs. To address different external environments, we have introduced three shielding types: F/UTP (overall aluminum foil shielding), SF/UTP (tinned copper braid + overall aluminum foil shielding), and S/FTP (overall tinned copper braid shielding + aluminum foil pair shielding), ensuring stable data transmission. The conductors are made of high-purity oxygen-free copper, employing precision wire drawing and insulation extrusion processes. Strict control over conductor concentricity ensures the cable’s transmission performance meets IEC 61156-5 requirements.

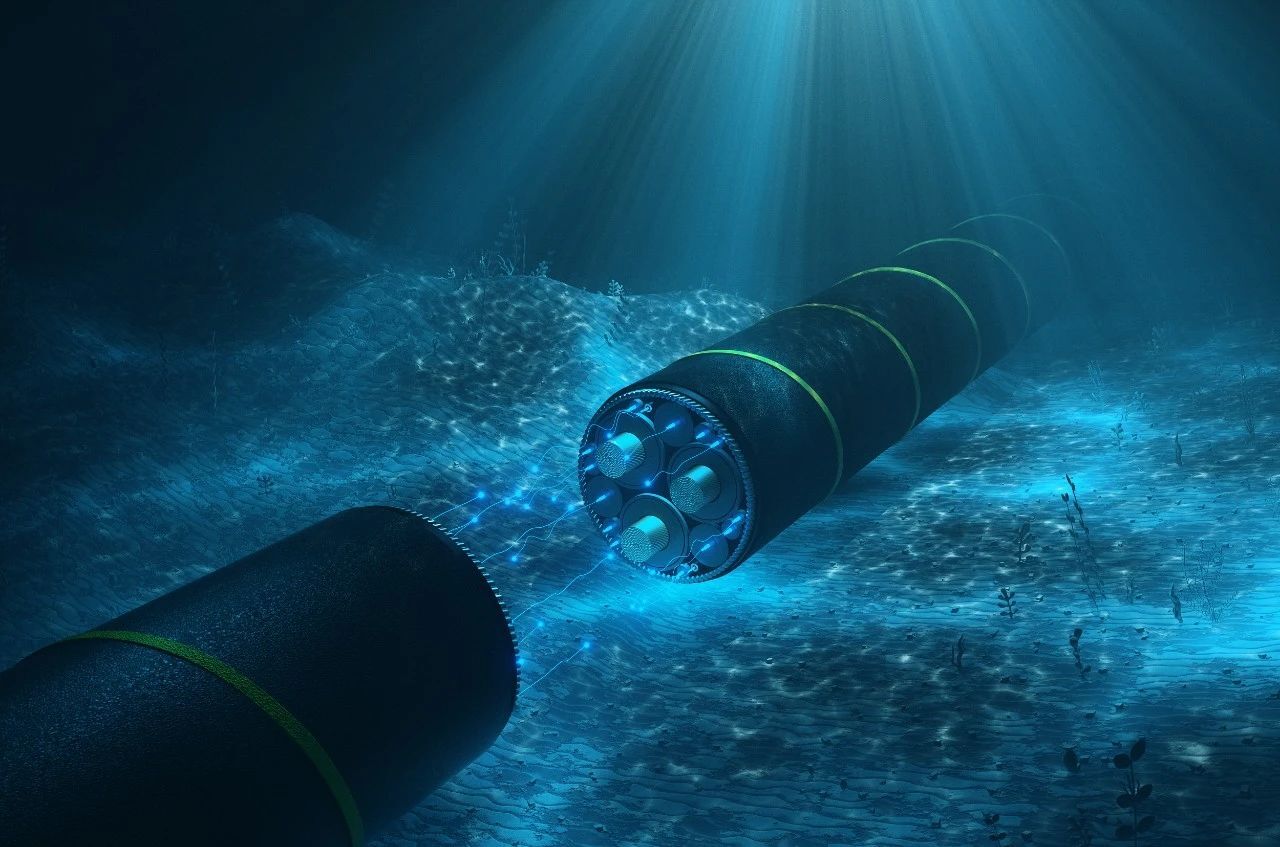

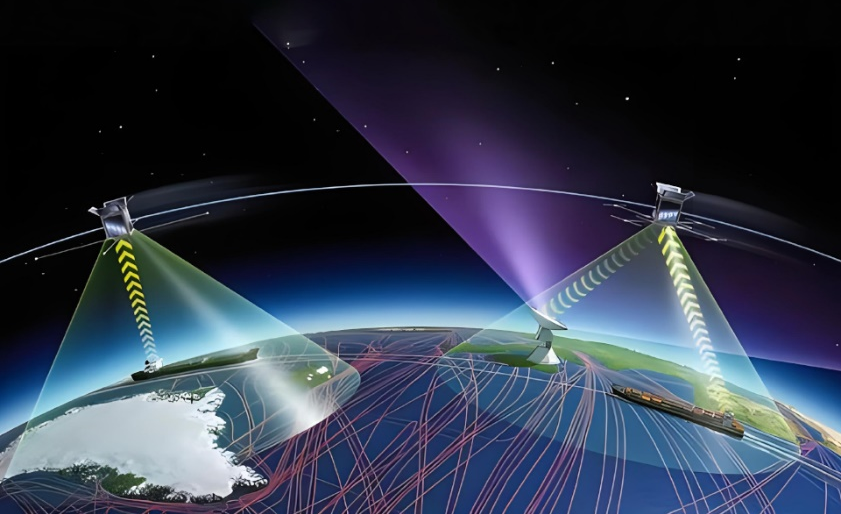

The fiber optic cables utilize low-loss fiber cores, meeting the demands of real-time massive data interaction for systems such as ship navigation, satellite communication, and IoT sensors. Immune to electromagnetic interference, they provide multi-scenario optical communication solutions ranging from single-mode to multi-mode and from indoor to outdoor applications.

Stringent Quality Control: Closed-Loop Full-Chain Management, Upholding Maritime Safety Standards

To ensure every meter of cable can adapt to the extreme operating conditions and long-term reliability requirements of vessels and offshore engineering, our company has established a full-chain quality control system covering “raw materials – production – testing – delivery,” based on the ISO9001:2015 quality management system framework and deeply integrated with LR’s specific technical specifications. This achieves dual assurance of “system compliance + classification society standards.” We rigorously screen qualified material suppliers and implement an “incoming inspection + system traceability” mechanism for key raw materials such as copper, optical fiber, insulation materials, and sheathing materials from each batch. Substandard materials are rejected, and results are recorded and handled according to the “Non-Conforming Product Control” procedure, eliminating quality risks at the source.

Core Advantages: Fortifying Maritime Communication Defenses with Technological Innovation

In offshore engineering scenarios, communication cables such as Ethernet cables and fiber optic cables often face threats like crude oil leaks and mud erosion. Through continuous optimization of materials and processes, our specialized Ethernet cables and fiber optic cables meet or even exceed the NEK 606 standard for offshore engineering cables. During the certification process, we simulated high-intensity mud environments in third-party laboratories. Whether subjected to 7 days of erosion by 100°C oil-based fluid or 56 days of immersion in high-concentration calcium bromide solution, the products’ mechanical performance remained within standard limits. Key characteristics such as signal transmission stability and attenuation maintained pre-test levels, with no significant sheath cracking, and volume change rates remained within controlled ranges.

Addressing the special requirements of enclosed ship spaces where fire spreads easily and critical equipment requires continuous power and communication, our marine Ethernet cables and fiber optic cables have achieved breakthroughs in “material-structure-performance” for flame retardancy and fire resistance safety design. They fully comply with stringent standards such as LR certification, IEC 60332-1-2, IEC 60332-3-22, and IEC 60331-2, ensuring core systems remain uninterrupted during fire scenarios and personnel safety is guaranteed. Both cable sheathing and insulation layers use low-smoke zero-halogen flame-retardant polyolefin materials, effectively inhibiting flame spread. Furthermore, smoke light transmittance exceeds 60%, and toxic gas release is ≤0.5%, preventing secondary hazards like smoke suffocation and toxic gas poisoning in enclosed ship spaces, thereby buying critical time for crew evacuation and firefighting. Structurally, high-purity mica tape wraps the conductors as a core insulation barrier. Even if the outer sheath carbonizes under high temperatures, the mica tape retains its insulation properties, preventing conductor short circuits. The cables can effectively withstand 830°C flames for 120 minutes under conditions including impact and water spray, meeting safe return to port requirements.

Leveraging innovative technology and material processes, our marine Ethernet cables and fiber optic cables operate stably within a temperature range of -40°C to 70°C, breaking the performance limitations of traditional cables. The products have passed the IEC 60794-1-21 mechanical performance test, excelling in over 10 rigorous assessments including low-temperature tensile, impact, and bending tests. Throughout the testing, optical cable attenuation variation was less than 0.2dB; Ethernet cable attenuation, return loss, and characteristic impedance variation rates all remained within the limits specified by IEC 61156-1. Whether for scientific expedition communication in icy polar regions or offshore platforms with high temperatures and salinity, our products ensure “zero interruption” in communication with reliable performance, making them an excellent choice for communication infrastructure in extreme temperature environments.

Against the backdrop of the global shipping industry transitioning toward intelligence and sustainability, stable and efficient communication systems have become key to ensuring safe navigation and enhancing operational efficiency. Our LR-certified marine Ethernet cables and fiber optic cables can be widely applied to various ship types, including bulk carriers, container ships, oil tankers, luxury cruise ships, and special-purpose vessels. They provide seamlessly adapted transmission support for ship navigation systems, Automatic Identification Systems (AIS), video surveillance systems, satellite communication equipment, and more.

Looking ahead, our company will accelerate the pace of classification society certification for specialized cables, integrate more rapidly into the construction of global vessel and offshore communication networks, and continue to drive technological upgrades in marine communication cables, providing safer and more reliable solutions for the maritime communication sector.

Post time: Dec-17-2025