Marine bus cables are critical communication media used to connect various automated equipment, control systems, instruments, and sensors on vessels and offshore installations. They are responsible for high-speed, stable, and interference-resistant data transmission, playing a vital role in ship power management, navigation systems, alarm systems, engine room monitoring, and more.

Background

Before the 1960s, communication and data transmission on ships primarily relied on simple point-to-point wiring for basic signal transmission. During this period, cables were mainly used for power transmission and basic control signals, with very limited communication capabilities.

In the 1960s, with the growing demand for ship automation, countries like Japan and Denmark introduced centralized equipment data acquisition systems. These systems used multiple cables to upload signals to a central computer for data collection and centralized monitoring. However, such systems were expensive and overly reliant on the central computer. A failure of the central computer would paralyze the entire system, posing significant risks to reliability and stability.

The 1970s saw significant advancements in integrated circuit technology and the widespread application of microcomputers. Ship data acquisition systems began transitioning from centralized to distributed architectures, using multiple microcomputer subsystems to replace the central computer, thereby improving system reliability and stability. However, limited by hardware compatibility, system scalability remained poor and struggled to meet increasingly complex ship automation demands.

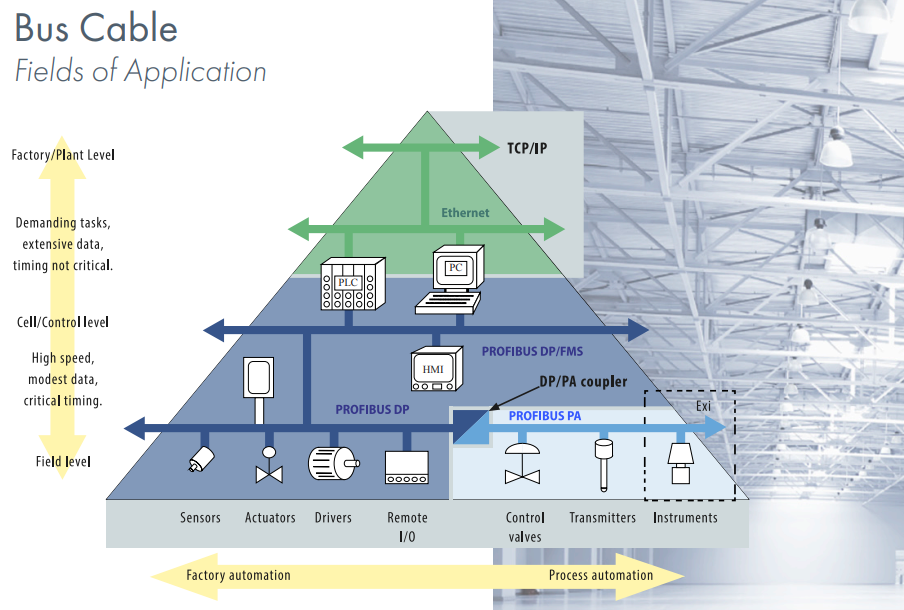

After the 1990s, fieldbus technology began to be applied in the shipbuilding industry. Fieldbus-based equipment data acquisition systems divided the architecture into field, intermediate, and centralized control layers, enabling local networking via the fieldbus. This structure greatly enhanced system scalability, significantly improved data transmission efficiency, and, due to reduced wiring, made maintenance more convenient. The introduction of fieldbus technology marked the shift of ship communication cables from traditional analog signal transmission to digital signal transmission, laying the foundation for the development of modern marine bus cables.

Entering the 21st century, with the trend towards ship intelligence and networking, demands for communication bandwidth and real-time performance have increased. Marine bus cables have also evolved towards higher speed, digitalization, and intelligence. Ethernet (e.g., EtherCAT) and high-speed CAN bus (e.g., CAN FD) are widely used in ships. New-generation marine bus cables offer higher transmission rates, stronger interference resistance, and longer transmission distances, capable of meeting modern ships’ demands for large-volume data and real-time communication.

Introduction

The marine environment is complex and variable. During voyages, ships are subject to factors such as wave impact, salt spray corrosion, temperature fluctuations, and electromagnetic interference. These special environmental conditions impose higher requirements on marine bus cables. Consequently, the structure and materials of marine bus cables are continuously updated to meet increasingly stringent maritime standards.

Currently, the typical structure of common marine bus cables is as follows:

- Conductor: Stranded tinned copper/stranded copper. Compared to pure copper, tinned copper offers better corrosion resistance.

- Insulation: Foamed Polyethylene (Foam-PE). Reduces weight while providing better insulation and lower attenuation.

- Shielding: Aluminum foil + tinned copper braid. The dual-shielded structure ensures long-distance transmission and provides stronger electromagnetic interference (EMI) resistance.

- Sheath: Low Smoke Zero Halogen (LSZH) flame-retardant polyolefin. Meets requirements for single-wire flame retardancy (IEC 60332-1), bunched cable flame retardancy (IEC 60332-3-22), as well as low smoke and halogen-free standards (IEC 60754, IEC 61034). This is currently the mainstream sheath material for marine cables.

The above describes the basic structure of marine bus cables. For more demanding applications, special constructions may be required. For instance, to meet fire resistance requirements (IEC 60331), a fire-resistant mica tape layer must be added within the insulation. For additional mechanical protection, a metal armor layer and an extra outer sheath may be necessary.

Classification

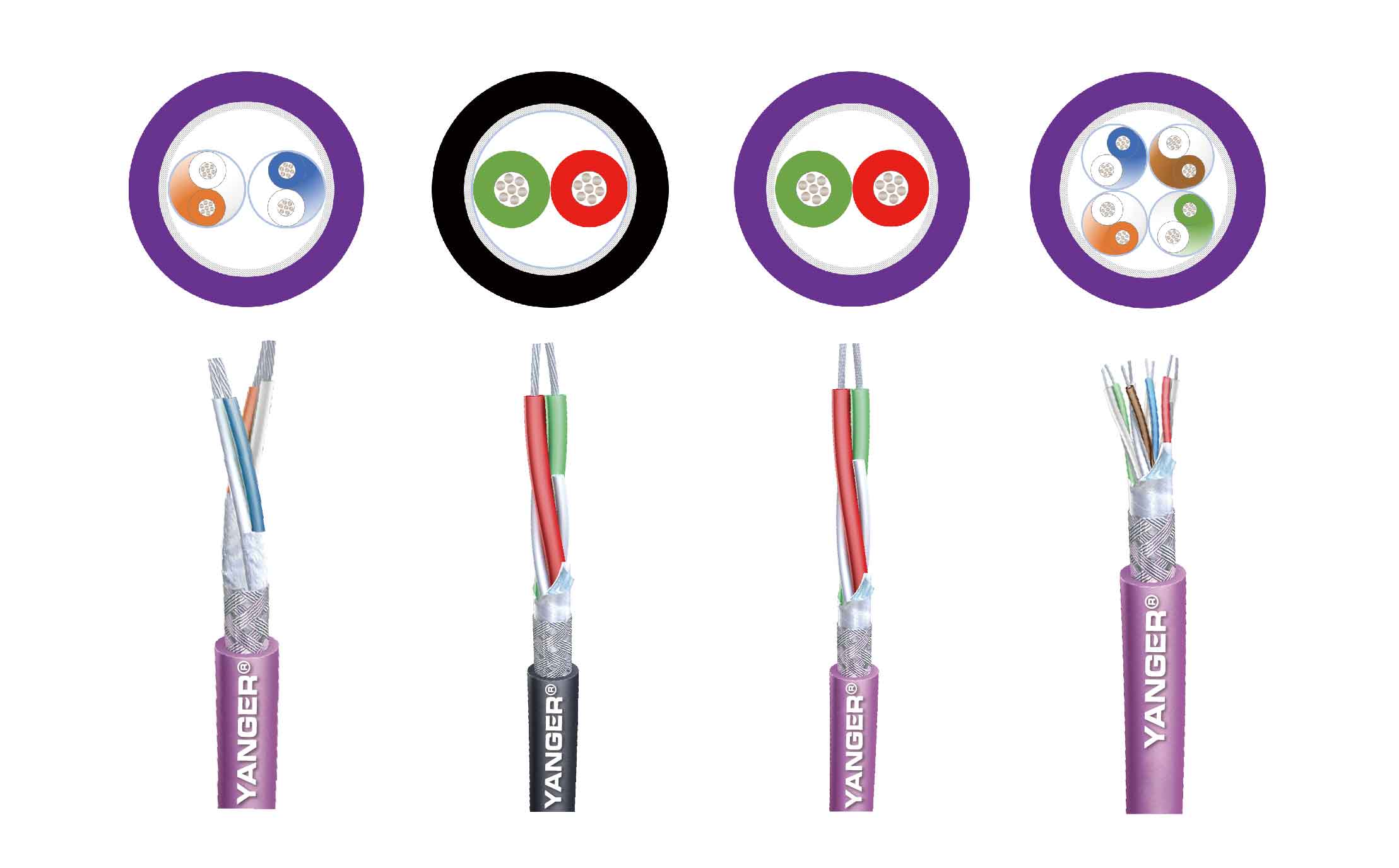

While the overall structure of marine bus cables is generally similar, different models serve various purposes. Common types of marine bus cables include:

- Profibus PA

- Profibus DP

- CANBUS

- RS485

- Profinet

Generally, Profibus PA/DP is used for process automation and PLC communication; CANBUS for engine control and alarm systems; RS485 for instrument communication and remote I/O; and Profinet for high-speed control systems and navigation networks.

Requirements

Marine bus cables must adhere to a series of standards and specifications to ensure their reliability and safety in the maritime environment.

- Salt Spray Corrosion Resistance: The marine environment contains high levels of salt, and salt spray is highly corrosive to cables. Marine bus cables must possess good salt spray corrosion resistance to prevent corrosion damage during long-term use.

- Electromagnetic Interference Resistance: Various equipment on ships generates strong electromagnetic interference. Marine bus cables must have excellent EMI resistance to ensure stable signal transmission.

- Vibration Resistance: Ships experience vibrations due to wave impacts during navigation. Marine bus cables need to have good vibration resistance.

- High and Low-Temperature Endurance: Marine bus cables must operate reliably under extreme temperature conditions, typically requiring an operational temperature range of -40°C to +70°C.

- Flame Retardancy: In the event of a shipboard fire, burning cables can produce large amounts of smoke and toxic gases, seriously threatening crew safety. The sheath of marine bus cables must be made of Low Smoke Zero Halogen (LSZH) materials and must meet the requirements for single-wire flame retardancy (IEC 60332-1), bunched cable flame retardancy (IEC 60332-3-22), as well as low smoke and halogen-free standards (IEC 60754-1/2, IEC 61034-1/2).

With the increasing completeness of standards and regulations, whether a product holds classification society certification has gradually become an important factor in evaluating its performance. Many projects also require marine bus cables to obtain certifications from classification societies such as DNV, ABS, and CCS.

Post time: Dec-17-2025