High Quality Stainless Steel Heating Cable for Insulation of Marine Desulphurization Equipment

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for High Quality Stainless Steel Heating Cable for Insulation of Marine Desulphurization Equipment, We, with open arms, invite all interested buyers to visit our website or contact us directly for further information.

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for China Defrost Heating Cable and Trace Cable, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

For used in power transmission and distribution system. suitable for outdoor use at temperature range

from -52℃ to +80℃. For VSD system application.

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for High Quality Stainless Steel Heating Cable for Insulation of Marine Desulphurization Equipment, We, with open arms, invite all interested buyers to visit our website or contact us directly for further information.

High Quality China Defrost Heating Cable and Trace Cable, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

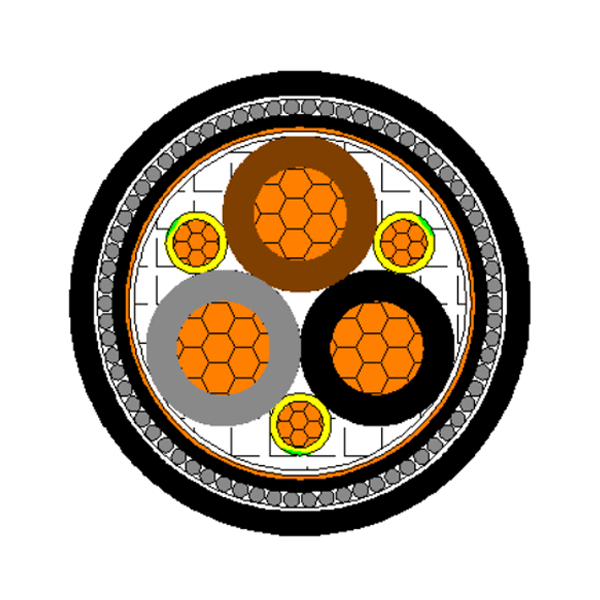

3.1 Conductor

Up to 25mm²: Plain annealed stranded circular non-compacted

copper conductor in accordance with IEC 60228 Class 2

Above 25mm²: Plain annealed stranded circular compacted copper

conductor in accordance with IEC 60228 Class 2

3.2 Insulation

Extruded XLPE compound comply with IEC 60502-1

Color:

3C: Black, Brown, Grey

3.3 Earth conductor

Three earth insulation conductors (color: Yellow/Green) arranged in

360°symmetrical configuration

3.4 Assembly and filler(optional)

The interstices between cores filled with non-hygroscopic

polypropylene rope to form substantially circular shape with a

suitable binder tape

3.5 Metallic Screen

A layer of copper tape helically overlap applied on the assembly

core

3.6 Separation sheath

Extruded LSZH ST8 compound comply with IEC 60502-1

Color: Black

3.7 Metal amour

A layer of galvanize steel wires with suitable binder tape helically

applied on the separation sheath

3.8 Outer sheath

Extruded LSZH ST8 compound comply with IEC 60502-1

Color: Black

For example:

EAC YANGER® IEC 60332-3-22 CU/XLPE/OA.SCR/LSZH/SWA/LSZH 3C×SIZE+3E×SIZE SQMM 0.6/1kV нг (А) – HF

-52°C~+40°C 2020 ****M

Note: “****M” meter marking by inkjet with increased sequence with numbering

“нг (А) – HF” at least every 1 metre appear on the cable

| Rated voltage, U0/U(Um), kV | 0.6/1(1.2) |

| Rated, operating temperature range, ℃ | -52~+80 |

| Min. installation temperature without preheating, ℃ | -20 |

| Max. conductor temperature in service, ℃ | 90 |

| Max. permissible short-circuit temperature,5 sec, ℃ | 250 |

| Min. bending radius, D overall diameter of cable | 15D |

| Flame retardant | IEC 60332-3-22 |

| Halogen Gas Emission | IEC 60754-1, < 0.5% |

| Low Smoke Emission | IEC 61034-1/2 |

| UV resistant | UL 1581 |

| Oil resistant | IEC60811(IRM 902 – 4h at 70°C,variation ±40%) |

| Oxygen Index(Sheath) | ASTM D 2863 |

| Cold bend | IEC 60811-1-4, -35℃ |

| Cold impact | IEC 60811-1-4 & CSA C22.2 No.38-10, -35℃ |

| Chemical resistance | Accidental |