Following the introduction of the basic knowledge of marine network cables in the previous issue, today we will continue to introduce the specific structure of marine network cables. Simply put, conventional network cables are generally composed of conductors, insulation layers, shielding layers, and outer sheaths, while armored network cables are composed of conductors, insulation layers, shielding layers, inner sheaths, armor layers, and outer sheaths. It can be seen that armored network cables not only have an additional layer of armor compared to conventional network cables, but also have an additional layer of protective inner sheath. Next, we will take everyone step by step to gain a deeper understanding of marine network cables.

1. Conductor

The materials of network cable conductors can be divided into tinned copper, pure copper, aluminum wire, copper clad aluminum, copper clad iron, and other types. According to the IEC 61156-5-2020 standard, solid annealed copper conductors with diameters between 0.4mm and 0.65mm should be used for network cables. At the same time, people have increasingly high requirements for the transmission rate and stability of network cables. Conductors with weak conductivity such as aluminum wire, copper clad aluminum, and copper clad iron have gradually been phased out in the market, with tinned copper and bare copper materials occupying the vast majority of the market. Compared to pure copper conductors, tinned copper has more stable chemical properties and can resist corrosion of conductors by oxidation, chemicals, and humidity, thereby maintaining circuit stability.

The network cable conductor structure is divided into solid conductor and stranded conductor. As the name suggests, solid conductor refers to a single copper wire, while stranded conductor is composed of multiple small cross-sectional copper wires wrapped in a spiral form, concentric. The most significant difference between stranded conductors and solid conductors is their transmission performance. Due to the larger the cross-sectional area of the wire, the lower the insertion loss. Therefore, the attenuation of stranded conductors is 20% -50% greater than that of solid conductors. And there are inevitably gaps between the strands of copper wire in the stranded conductor, resulting in higher DC resistance. In most scenarios, engineers tend to use solid conductor network cables. When encountering special situations that require narrow spaces and flexible wiring, they will use more flexible stranded conductors to meet installation requirements.

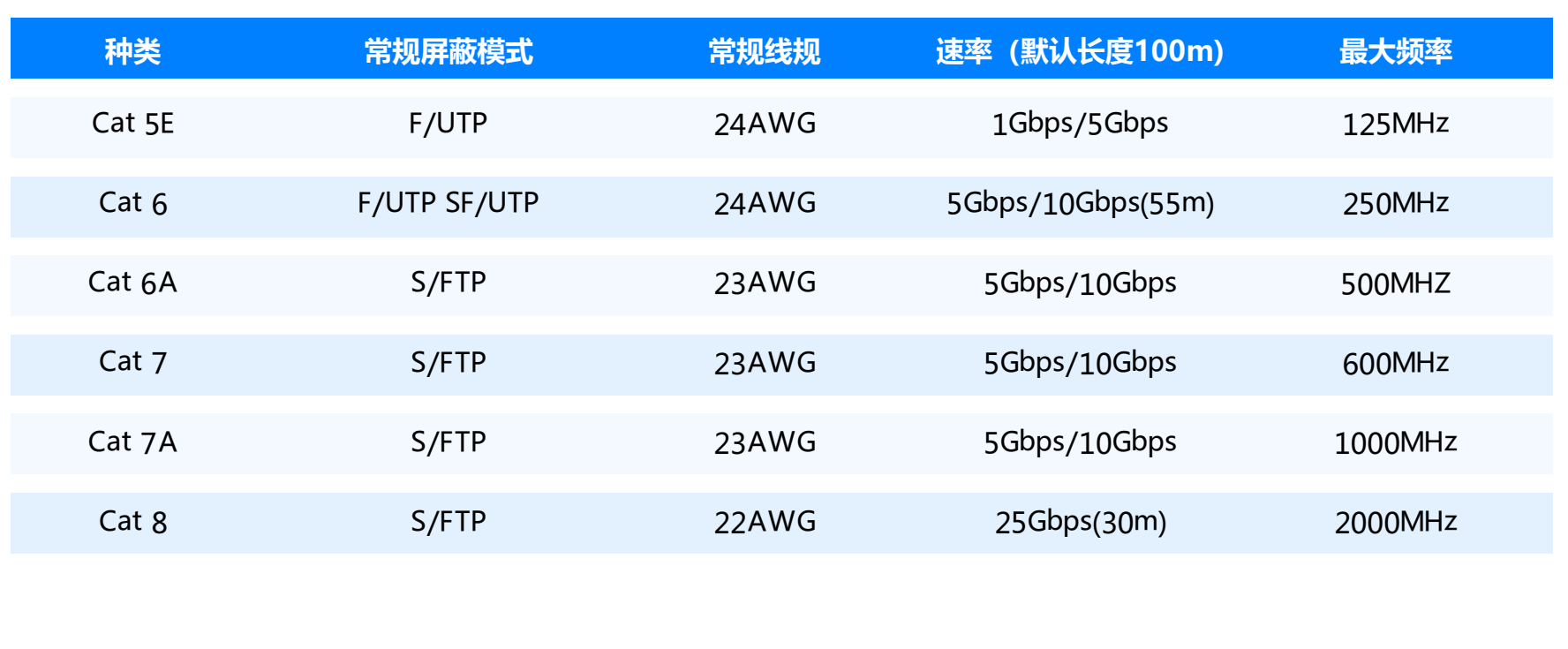

Most network cables will use two specifications of conductors: 23AWG (0.57mm) and 24AWG (0.51mm). CAT5E uses 24AWG conductors, while CAT6, CAT6A, CAT7, and CAT7A require better transmission performance, so 23AWG conductors will be used. Of course, the IEC specifications do not clearly classify the wire specifications for various types of network cables. As long as the manufacturing process is excellent and the transmission performance meets the requirements, 24AWG conductors are also suitable for CAT6 and above network cables.

2. Insulation

The insulation layer of the network cable is mainly used to prevent leakage of signals during transmission in the cable, thereby avoiding data leakage. According to the IEC60092-360 standard and domestic wiring specifications such as GB/T 50311-2016, high-density polyethylene (HDPE) or foamed polyethylene (PE Foam) materials are generally used as insulation materials for marine network cables. High density polyethylene has excellent resistance to high and low temperatures, strong mechanical properties, high dielectric constant, and good environmental stress. Due to its excellent performance, it is widely used. Foamed polyethylene is suitable for high transmission rate network cables with CAT6A and above specifications due to its better dielectric properties.

3. Cross skeleton

The cross skeleton, also known as the cross keel, is used to separate the four pairs of network cables in four different directions, thereby reducing crosstalk between the pairs; The cross keel is generally composed of HDPE with a diameter of 0.5mm. Category 6 and above network cables are more sensitive to signal “noise” due to the need to transmit data of 1Gps or more. Higher requirements for anti-interference ability of cables. Therefore, for Category 6 and above network cables that do not use aluminum foil wire pair shielding, a cross skeleton isolation of four pairs of wires will be used.

However, there is no use of a cross skeleton for Category 5 network cables and network cables shielded with aluminum foil pairs. Because the transmission bandwidth of the Super Five network cable itself is not large, the twisted pair structure of the cable itself can meet the anti-interference requirements. Therefore, there is no need for a cross skeleton. The aluminum foil used for shielding the network cable itself can prevent high-frequency electromagnetic interference. Therefore, there is no need to use a cross skeleton. The tensile rope plays a role in preventing the network cable from being stretched and affecting its performance. Currently, major cable manufacturers mostly use fiberglass or nylon ropes as tensile ropes.

4. Shield

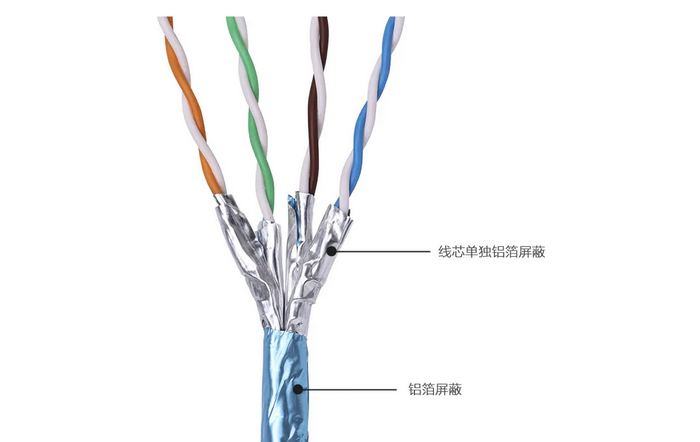

The shielding layer of the network cable refers to aluminum foil and woven mesh, and the shielding layer is mainly used to shield electromagnetic interference and ensure stable signal transmission. The shielding layer of a single shielded network cable is only one layer of aluminum foil, with a thickness of not less than 0.012mm and a wrapping overlap rate of not less than 20%. A layer of PET plastic film, commonly known as Mylar, will be wrapped between the cable and the aluminum foil single shielding layer to isolate the current flow between the cable and the metal shielding layer and prevent excessive current from damaging the cable. There are two forms of double shielded network cables, one is SF/UTP (external braiding+aluminum foil overall shielding), and the other is S/FTP (external braiding+wire to aluminum foil partial shielding). Both are composed of aluminum foil and woven mesh, where the woven mesh is made of tinned copper wire with a diameter of no less than 0.5mm, and the weaving density can be customized according to environmental requirements. Generally, there are several commonly used gears such as 45%, 65%, and 80%. According to the IEC60092-350 design standard for marine cables, a grounding wire in contact with the metal surface of the shielding layer needs to be added to a single-layer shielded network cable to prevent static damage, while a double shielded network cable does not need to be added as the metal braid layer can release static electricity.

5. Armor

Armored network cable refers to a network cable with a metal material armor protection layer. The purpose of adding an armor layer to the network cable is not only to enhance mechanical protection such as tensile strength and compressive strength to extend its service life, but also to improve anti-interference performance through shielding protection. The armor form of marine network cables is mainly woven armor, made of galvanized steel wire, copper wire, metal plated copper wire, or copper alloy wire that meets the ISO7959-2 standard. In the actual production process, the vast majority of wire armor is made of galvanized steel wire weaving (GSWB) and tinned copper wire weaving (TCWB). GSWB material has higher mechanical strength and is more resistant to high temperatures, making it suitable for places with high requirements for cable strength; TCWB material has stronger flexibility, smaller bending radius, but lower strength, and is suitable for places with high requirements for cable toughness.

6. Jacket

The outer sheath of the network cable is commonly known as the outer sheath. Its function is to wrap the four pairs of network cables in a space, facilitating wiring, and protecting the four pairs of wires in the network cables. The outer sheath requires a round and uniform appearance, forming a tight homogeneous whole, and covering the components below. When peeling off the outer sheath, it will not cause damage to the internal insulation or shielding. According to the requirements of DNV Classification Society, the thickness of the outer sheath of the marine network cable Dt=0.04 · Df (outer diameter of the inner structure of the sheath)+0.5mm, and the minimum thickness is 0.7mm. The sheath material of marine network cables is mainly low smoke halogen-free flame retardant polyolefin (LSZH), which is classified into three categories: LSZH-SHF1, LSZH-SHF2, and LSZH-SHF2 MUD, and meets the material range specified in IEC60092-360. When LSZH material is burned, the smoke density is very low and it does not contain halogens (fluorochlorobromine iodine astatine), so it does not produce a large amount of toxic gases. The previous issue introduced that LSZH-SHF1 is the most common and suitable for most indoor conventional environments, while LSZH-SHF2 and LSZH-SHF2 MUD are suitable for more severe environments, such as FPSO and offshore power plants.

Post time: Nov-09-2023