2019 High quality Flexible Tinned Copper Power Cable Suitable for General Purpose Automotive and Marine Applications

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for 2019 High quality Flexible Tinned Copper Power Cable Suitable for General Purpose Automotive and Marine Applications, We warmly welcome you to build cooperation and generate a brilliant long term together with us.

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for China Power Wire and Power Cable, Profession, Devoting are always fundamental to our mission. Now we have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

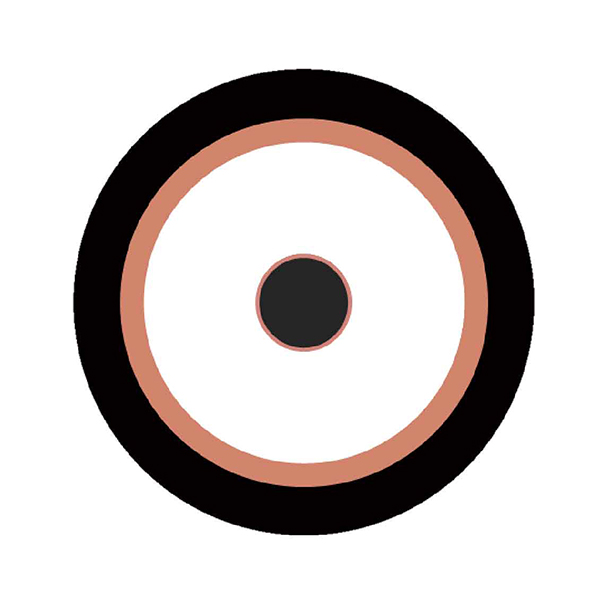

| Conductor: | Cu-tube |

| Conductor Size: | 9.45 ± 0.1 mm |

| Insulation: | Cellular PE |

| Insulation OD: | 23.2 ± 0.35 mm |

| Screen: | Corrugated Cu-tube |

| Outer jacket: | SHF2 |

| Outer Jacket OD: | 30.0 ± 0.20 mm |

| Outer Jacket Color: | Black (optional) |

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for 2019 High quality Flexible Tinned Copper Power Cable Suitable for General Purpose Automotive and Marine Applications, We warmly welcome you to build cooperation and generate a brilliant long term together with us.

2019 High quality China Power Wire and Power Cable, Profession, Devoting are always fundamental to our mission. Now we have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

| Temperature Range: | -40°C – 70°C |

| Halogen acid gas, Degree of acidity of gases: | IEC 60754-1/2 |

| Jacket, Insulation material: | IEC 60092-360 |

| Smoke Emission: | IEC 61034-1/2 |

| Flame Retardant: | IEC 60332-3-22 |

| UV-resistant: | UL 1581 |

| Conductor resistance: | ≤1.3 Ω/km |

| Screen resistance: | ≤1.28 Ω/km |

| Peak RF voltage: | 3.3 KV |

| Peak power rating: | 92 KW |

| Insulation resistance: | 10 GΩ/km |

| Capacity: | 74.2 pF/m |

| Impedance: | 50 ± 2 Ω |

| Frequency: | Max 5000 MHZ |

| Velocity factor: | 88% |

| Min. bending radius: | 150 mm |

| Recommended clamping space: | 1 m |

| Frequency [MHz] | Nominal attenuation [dB/100m] max.105% | Power rating [kW] |

| 50 | 0.70 | 11.0 |

| 88 | 1.00 | 8.5 |

| 100 | 1.12 | 8.0 |

| 200 | 1.50 | 5.6 |

| 300 | 1.90 | 4.5 |

| 450 | 2.40 | 3.6 |

| 500 | 2.50 | 3.4 |

| 700 | 2.95 | 2.8 |

| 800 | 3.00 | 2.6 |

| 900 | 3.40 | 2.5 |

| 1000 | 3.70 | 2.3 |

| 1400 | 4.45 | 1.9 |

| 1800 | 5.09 | 1.7 |

| 2000 | 5.20 | 1.6 |

| 2400 | 5.90 | 1.4 |

| 3000 | 6.90 | 1.2 |

| 3400 | 7.93 | 1.2 |

| 4000 | 8.50 | 1.0 |

| 5000 | 9.26 | 0.9 |